Description

Special dry mortar production line is an advanced industrial system designed for the efficient and precise manufacturing of various types of specialized mortars. These mortars are engineered to meet specific performance requirements, such as enhanced strength, durability, thermal insulation, waterproofing, and fire resistance. Special dry mortar production line integrates state-of-the-art technology to ensure consistent quality, high productivity, and minimal environmental impact.

Key Components of the Special Dry Mortar Production Line:

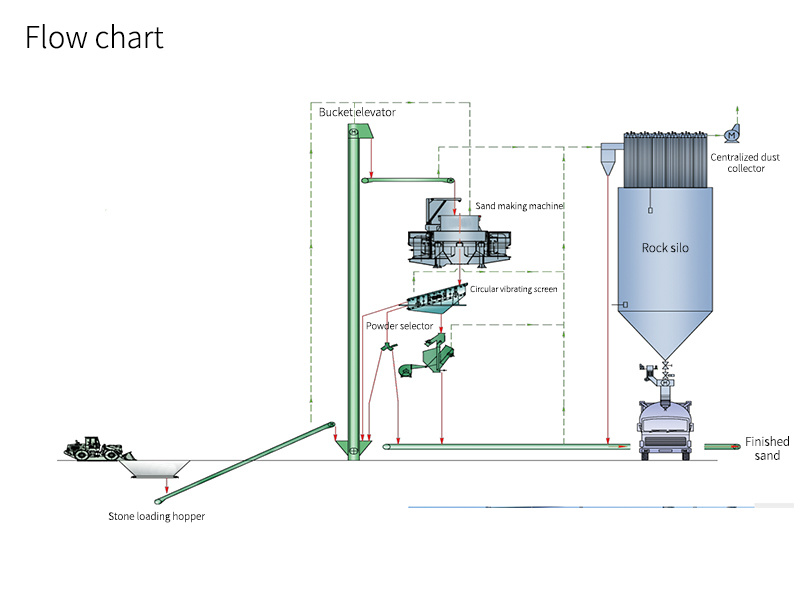

1. Raw Material Storage and Conveying System

Silos and Hoppers: For storing bulk materials like cement, sand, and additives.

Conveying Systems: Including screw conveyors, bucket elevators, and pneumatic conveyors to transport raw materials to the mixing unit.

2. Weighing and Batching System

Precision Weighing Scales: Ensure accurate measurement of each component.

Automated Batching Controls: Facilitate precise ingredient ratios for consistent product quality.

3. Mixing Unit

High-Speed Mixers: Equipped with advanced mixing blades to achieve homogeneous blending of dry and wet ingredients.

PLC Control System: Allow for automated and customizable mixing cycles.

4. Packaging System

Automatic Bagging Machines: For filling and sealing bags of various sizes.

Palletizing Robots: To stack and organize packaged products for efficient storage and transportation.

5. Dust Collection and Environmental Controls

Dust Filters and Cyclones: To capture and reduce airborne particles, ensuring a clean working environment.

Emission Control Systems: To minimize the release of pollutants and comply with environmental regulations.

6. Quality Control and Testing

In-line Sensors and Monitors: For real-time monitoring of product quality.

Laboratory Equipment: For detailed analysis and testing of mortar samples to ensure they meet specified standards.

Advantages of the Special Mortar Production Line:

● High Efficiency: Automated processes reduce labor costs and increase production speed.

● Consistent Quality: Precise control over ingredient ratios and mixing processes ensures uniform product quality.

● Versatility: Capable of producing a wide range of specialized mortars to meet diverse application needs.

● Sustainability: Incorporates eco-friendly technologies to reduce waste and energy consumption.

Its technical parameters are as follows:

Model | Mixer | Power(kw) | Theoretical capacity(t/h) | Floor area(m²) |

GDW1200 | JLD1200 | 100 | 10 | 200 |

GDW2000 | SW2000 | 150 | 20 | 200 |

GDW3000 | SW3000 | 200 | 30 | 300 |

GDW4000 | SW4000 | 250 | 40 | 300 |

Tile Adhesive Putty Powder Special Mortar Plant

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?