Nov 28,2025

The Four Major Hazards of Abandoning Intelligent Control Systems in Dry-Mix Mortar Production Lines

In the current era of large-scale and refined development of the dry-mix mortar industry, intelligent control systems have become the core "brain" of production lines. However, some enterprises still cling to the traditional manual operation mode, unaware that this choice is planting multiple hidden risks in production and operation, seriously restricting the enterprises' competitiveness and sustainable development.

Nov 26,2025

Advantage Analysis of Dry Mortar Production Lines

This article examines the key benefits of dry mortar production lines, highlighting their role in enhancing efficiency, reducing costs, ensuring quality, and promoting sustainability. Key advantages include automated processes that boost output and minimize labor, precise batching for consistent product quality, waste reduction through optimized resource use, environmental gains from lower dust emissions and energy savings, operational flexibility for diverse formulations, and improved workplace safety. These factors make dry mortar lines essential for modern construction industries seeking scalable and eco-friendly solutions.

Nov 04,2025

Guided by the national "dual carbon" strategy and green development policies, the traditional dry mortar industry—characterized by high energy consumption and high emissions—faces an urgent need for transformation and upgrading. Promoting equipment upgrades, especially the green renovation of existing old plants, has become an inevitable choice for the sustainable development of the industry.

Oct 09,2025

Amid the global wave of construction material upgrading, dry-mix mortar, leveraging its eco-friendly and high-efficiency characteristics, has become a crucial vehicle for promoting green building development in many countries. Its application and development have always centered on environmental protection requirements and functional needs.

Aug 29,2025

In today's construction industry that pursues high efficiency and quality, dry-mixed mortar has gradually become a preferred material in construction due to its numerous advantages.

Aug 26,2025

In recent years, the state has intensively introduced policies related to green development, clearly requiring an increase in the proportion of ready-mixed mortar used and restricting on-site mixing. These measures have brought new development opportunities to the dry-mix mortar equipment industry. Against this backdrop, Zhongqinglin Heavy Industry has actively responded to the policy call. Its independently developed dry-mix mortar production line, with advanced technology and green attributes, has become a key driver for the industry's upgrading.

Aug 14,2025

The green transformation of the current construction industry is extremely urgent. In some regions, the extensive practice of "digging pits to landfill" construction waste has become an ecological "scourge", while dust pollution in dry-mix mortar production has long been a persistent pain point plaguing the industry.

Aug 13,2025

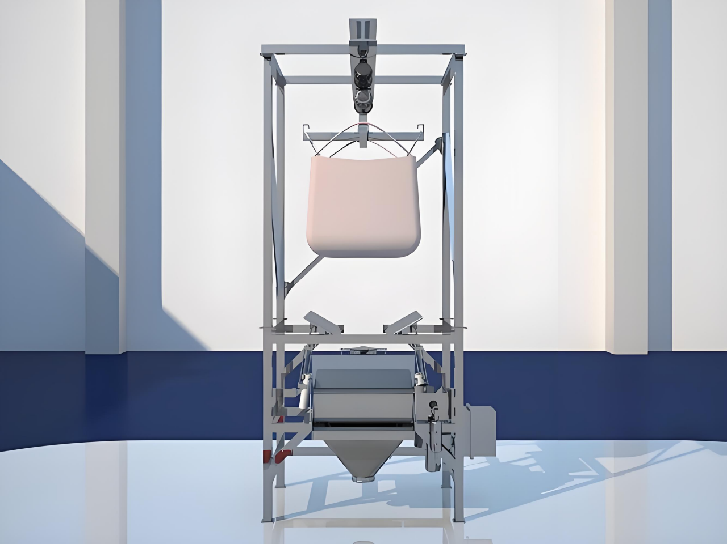

The Important Role of Aggregate Lifting Systems

In dry-mix mortar production lines, the aggregate lifting system serves as the core hub connecting raw material preprocessing and mixing stages. It is responsible for transporting aggregates such as sand and quartz sand from storage areas or screening/drying equipment to subsequent metering and mixing processes. The rationality of its design directly affects the efficiency, stability, and environmental performance of the production line. Its specific advantages can be elaborated from the following dimensions:

Aug 11,2025

Development Prospect of Dry-Mix Mortar Production Lines

Against the backdrop of global innovation in the construction industry, dry-mix mortar production lines, as key equipment, boast broad prospects in overseas markets. According to relevant reports, the global market size will reach $12.472 billion in 2025 and is projected to rise to $20.5251 billion by 2033, with a compound annual growth rate of 6.425% from 2025 to 2033, indicating a strong upward momentum.

Aug 09,2025

The Significant Role of Dry-Mix Mortar in Production and Daily Life

As a modern construction material, dry-mix mortar plays a multifaceted and significant role in production and daily life. In terms of improving construction quality, its industrialized production mode eliminates quality fluctuations caused by traditional on-site mixing through precise proportioning. After being used in a commercial complex project, the deviation in verticality and flatness of the walls was minimal. Meanwhile, formulations added with polymers enhance adhesion and durability, significantly reducing the hollowing rate in tile installation. The external wall insulation systems of residential communities have maintained excellent performance after long-term testing, extending the service life of buildings.

Contact Us

E-mail :

sisoulzg@126.com

Phone/WhatsApp:

+86 13963913992

Address:

Yuhuangling Industrial Park, Chengyang District, Qingdao, China