-

ContactIs a professional manufacturer of construction machinery integrating research and development, manufacturing, sales, installation and after-sales service.

-

ProductsContactIs a professional manufacturer of construction machinery integrating research and development, manufacturing, sales, installation and after-sales service.

-

ContactIs a professional manufacturer of construction machinery integrating research and development, manufacturing, sales, installation and after-sales service.

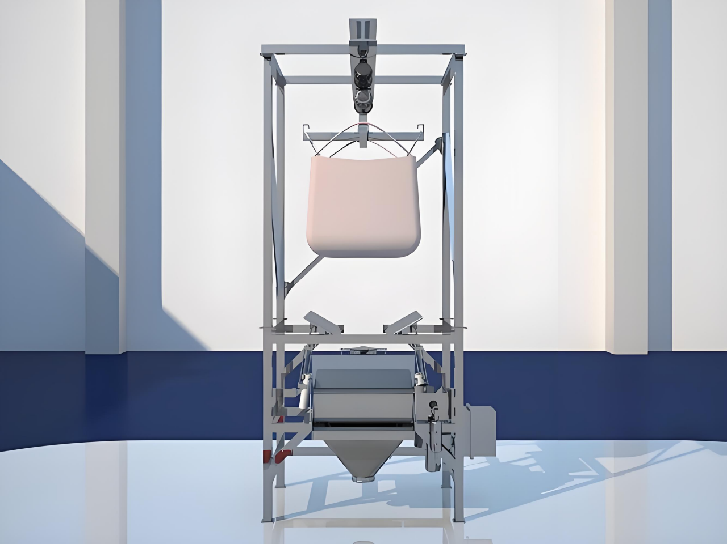

The Important Role of Aggregate Lifting Systems

In dry-mix mortar production lines, the aggregate lifting system serves as the core hub connecting raw material preprocessing and mixing stages. It is responsible for transporting aggregates such as sand and quartz sand from storage areas or screening/drying equipment to subsequent metering and mixing processes. The rationality of its design directly affects the efficiency, stability, and environmental performance of the production line. Its specific advantages can be elaborated from the following dimensions:

Aug 13,2025

In dry-mix mortar production lines, the aggregate lifting system serves as the core hub connecting raw material preprocessing and mixing stages. It is responsible for transporting aggregates such as sand and quartz sand from storage areas or screening/drying equipment to subsequent metering and mixing processes. The rationality of its design directly affects the efficiency, stability, and environmental performance of the production line. Its specific advantages can be elaborated from the following dimensions:

1. Efficient Conveying to Enhance Production Continuity

The core function of the aggregate lifting system is to achieve "uninterrupted transfer" of aggregates, with its efficiency reflected in:

Adaptability to Large Conveying Capacity: The lifting capacity can be flexibly configured according to the scale of the production line. Lifting machines supporting small-scale production lines can achieve a conveying capacity of 5-10 tons per hour, while large-scale production lines can exceed 50 tons per hour. This precisely matches the output rhythm of aggregates after drying and screening, avoiding raw material accumulation or "material shortage" in subsequent processes.

Strong Vertical/Inclined Conveying Capacity: Compared with horizontal conveyors, the lifting system can achieve vertical or large-angle (30°-90°) conveying, significantly saving workshop floor space. For example, bucket elevators continuously scoop aggregates through buckets, with a vertical lifting height of 10-30 meters, easily connecting equipment layouts across different floors (such as conveying from ground drying equipment to the second-floor metering bin).

2. Precise Quantity Control to Ensure Raw Material Proportioning Accuracy

The core of dry-mix mortar quality lies in "precise proportioning". The lifting system lays the foundation for the metering process through technical design:

Uniform Feeding: Some lifting equipment (such as screw elevators) can achieve "continuous quantitative feeding" through the uniform rotation of screw blades, avoiding metering errors caused by sudden large influx of aggregates into the metering bin.

Adaptability to Multiple Aggregate Types: For aggregates with different particle sizes (0.1-5mm) and densities (such as fine sand and gravel), adjustments can be made to bucket shapes (deep buckets, shallow buckets) or screw parameters (pitch, rotation speed) to ensure no segregation or residue during conveying, thus maintaining stable physical properties of raw materials.

Request Quote

Note: Please be sure to fill in the information accurately and keep communication open, we will get in touch with you as soon as possible

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Inquiry:

WhatsApp:

Email:

导航下拉添加类名.active

在线客服添加返回顶部

右侧在线客服样式 1,2,3 3

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地