Description

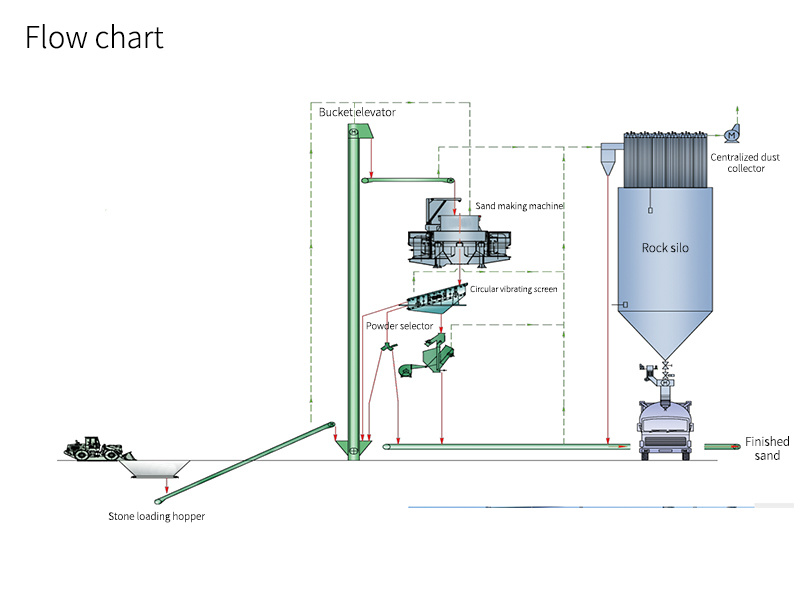

To ensure the stable and reliable operation of the high-quality sand making tower plant and ensure the quality effect of the core components, the core components of the sand making tower plant are: vertical shaft impact crushing sand making machine, high-frequency circular vibrating screen, powder sorting machine, return device, finished material conveying device, etc.

1. Sand making machine. High production efficiency, strong adaptability of raw materials, good crushing size, high durability and many advantages. The transmission part adopts a special sealing structure to prevent the bearing simple oil leakage, reduce the transmission system failure, the crushing method is divided into stone beating, stone beating, and the mixed sand making machine, to achieve the finished sand shaping function, reduce the needle sheet sand, improve the finished sand roundness. Reasonable selection according to the production use, equipped with oil temperature protection, computer independent protection, strengthen the protection of the main engine, in the case of abnormal monitoring of the sand making machine, automatic alarm and start and stop, maximize the protection of the sand making machine, increase the life of the equipment; The structure and process of the impeller and the surrounding protection plate are adjusted, and the service life of the impeller part is improved compared with that of the previous equipment under the condition of crushing the same material.

2. Iron remover. The use of strong magnetic water magnetic iron remover protects the sand making equipment at the source and prevents hard metal objects from entering the sand making system and causing damage to important components such as pipes, sand making machines and round vibrating screens.

3. Half warehouse batching system. Variable frequency feed conveyor belt, feed rate adjustable and controllable. The use of raw materials can be monitored and counted by using the belt weighing device.

4. Powder selection equipment. In the production process of machine-made sand crushing, a part of stone powder will be produced, and the high content of stone powder will cause the hollow drum cracking and other defects in the process of mortar wall. The finished sand will be dedusted to make the powder content adjustable and controllable, that is, the powder content of finished sand can be controlled by 3%-15% and the powder content of raw materials can be adjusted and controlled.

5. Fully closed feeding system. Machine sand dust control than commercial mixing station, mortar equipment is more difficult to deal with, the main difficulties exist in the transport link, raw materials and finished products determined by the characteristics of raw materials and finished products can not use the spiral machine duct such a closed transport mode, can only use the tape machine conveyor, and the tape machine closed treatment has been a problem in closed treatment. In order to solve this problem, our company uses a number of measures to control the dust in the conveyor process:

● The sealing treatment of the conveyor belt, the use of a large number of dust cover, and the dust cover on both sides of the fixed thick rubber pad, rubber pad directly with the belt zero gap butt, dust cover and conveyor belt between the formation of a closed space design, in order to ensure the sealing effect, the machine sand belt machine adopts a dense roller group design, that is, each less than 20 cm apart a group of rollers, A large number of dense idlers ensure the sealing effect at the same time, but also make the tape machine run more stable, at the same time to replace the rubber pad with a humanized design, the replacement of the rubber pad is very simple, because the rubber pad only plays a sealing role, does not play a wear-resistant effect, the actual wear of the rubber pad replacement frequency is very low.

● The key parts use large air volume active pulse dust collector, the key nodes in the conveying process are equipped with large air volume active pulse dust collector, belt conveyor into the elevator interface, loading into the elevator interface, these key nodes are equipped with large area active pulse dust collector

● The formation of negative pressure, after the above design links, more than 90% of the dust is controlled, in order to completely realize the dust-free production of mechanical sand, the large air volume fan used in the non-dynamic dedusting is connected with the tape machine, directly forming a negative pressure situation, even if the sealing is not strict, due to the negative pressure formed in the channel, the dust cannot overflow and will enter the dust collector again.

Technical Parameters

VK100 sand making production line technical parameters | ||||

1. | Theoretical productivity | ≤4.75mm productivity 100t/h (raw material is limestone, including powder) | 1 | Powder ≤0.075mm |

2. | Crushing system | Vertical shaft impact type VK100; Power 2x220KW | 1 |

|

3. | Conveying system | Material lifting conveyor PD800 | 2 |

|

NE300 plate chain elevator | 1 | |||

4. | Screening and selecting system | Powder selecting machine VF1250 | 1 | The diameter of vibrating screen is confirmed by the user |

Material feedback device | 1 | |||

Vibrating screen 3YK2470 | 1 | |||

5. | Material storage system | Stone powder silo:200t | 1 |

|

6. | Dust collecting system | Centralized dust collector | 1 | Collect dust from sand making line |

25 bags pulse bulk dust collector | 1 | |||

7. | Bulking loading machine |

| 1 | Pack stone powder in bulk |

8. | Concrete structure | Concrete sand making tower plant | 1 | Stable, reliable and easy to install |

High-Quality Sand Making Tower Plant

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?