Description

Twin-shaft horizontal mixer is the high-tech advanced one for dry mortar. The double shafts along with the replaceable wear-resistant paddles run in counter-rotation to turn over the materials. All the materials will be lifted into non-gravity status and then fall down to form a cross mixing. Thus we can get perfect mixing in very short time and almost all the materials can be emptied through full bottom discharge valve. Besides, the mixer can be equipped with several flying knives, which are used for cutting up something tougher or some agglomerate additives like fibre. Both the wear-resistant paddles and the choppers have improved the mixing stability, mixing quality, mixing speed, and keep long-term service life. Twin-shaft horizontal mixers can be used independently, also can be used in the dry mortar mixing plant or tower. They are applicable to the normal construction project, road, bridge site, or dry mortar production factory.

The technical parameters are as follows:

Model | Volume/L | Power/KW | Weight/KG | Load factor | Flying-cutter/SET |

SW500 | 500 | 7.5 | 1000 | ≤0.7 | 4 |

SW1000 | 1000 | 11-15 | 2500 | ≤0.7 | 4 |

SW2000 | 2000 | 18.5-37 | 3500 | ≤0.7 | 4 |

SW3000 | 3000 | 37-45 | 4000 | ≤0.7 | 4 |

SW4000 | 4000 | 45-75 | 5000 | ≤0.7 | 4 |

SW6000 | 6000 | 75-100 | 6000 | ≤0.7 | 6 |

SW10000 | 10000 | 100-150 | 9000 | ≤0.7 | 6 |

Twin-shaft Dry Mortar Mixer

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

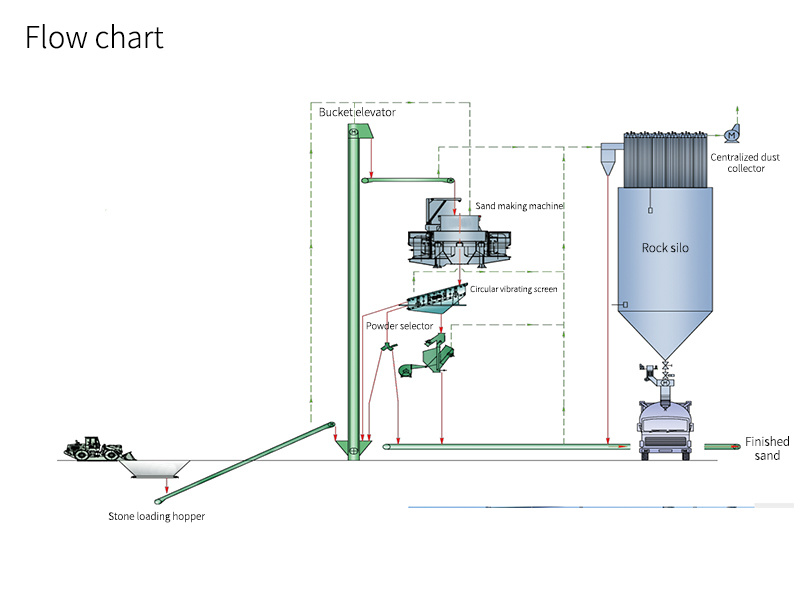

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?