Description

Dry mortar palletizing system is an advanced and automated equipment designed for the palletizing of dry mortar products in the construction materials industry. It mainly has the following characteristics and functions:

● High Automation: It can automatically complete a series of operations such as picking up, transporting and stacking dry mortar bags, greatly reducing labor intensity and improving production efficiency. With advanced robotic arms and conveying devices, it can continuously work without interruption, palletizing a large number of bags within a short time.

● Precise Positioning: Utilizes advanced sensing and positioning technologies to ensure accurate placement of each dry mortar bag on the pallet. The positioning accuracy can reach a very high level, usually within a few millimeters, which guarantees the stability and neatness of the palletized stack.

● Flexible Adaptability: Can adapt to different specifications of dry mortar bags and pallets. Whether it is a 25-kilogram or 50-kilogram bag, or pallets of different sizes and shapes, the system can adjust parameters through the control system to complete the palletizing task efficiently.

● Reliable Performance: The system is composed of high-quality mechanical and electrical components, with high reliability and stability. It has a low failure rate and can work stably for a long time under harsh industrial environments. Regular maintenance can further extend its service life.

● Intelligent Control: Equipped with an intelligent control system, which allows operators to set parameters, monitor the operation status and adjust the working mode through the touch screen. It also has functions such as fault self-diagnosis and alarm, which can quickly locate and solve problems, reducing downtime.

In conclusion, the dry mortar palletizing system is an important part of the dry mortar production line, which helps to improve the overall production efficiency, product quality and logistics management level in the construction materials industry.

The technical parameters are as follows

Packing speed | 600-1000bags/hour |

Packing weight | 10-50kg |

Power supply | 380V 50Hz Triple-PHA, 4Wires |

Stacking layers | 1-12 |

Pallet requirements | Customize |

Bags | Open mouth woven bag, valve bag, gusset bag, poly liner, etc. |

Optional | Wrapping machine, coding machine, etc. |

TAG:

Packed Dry Mortar Palletizing Machine

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

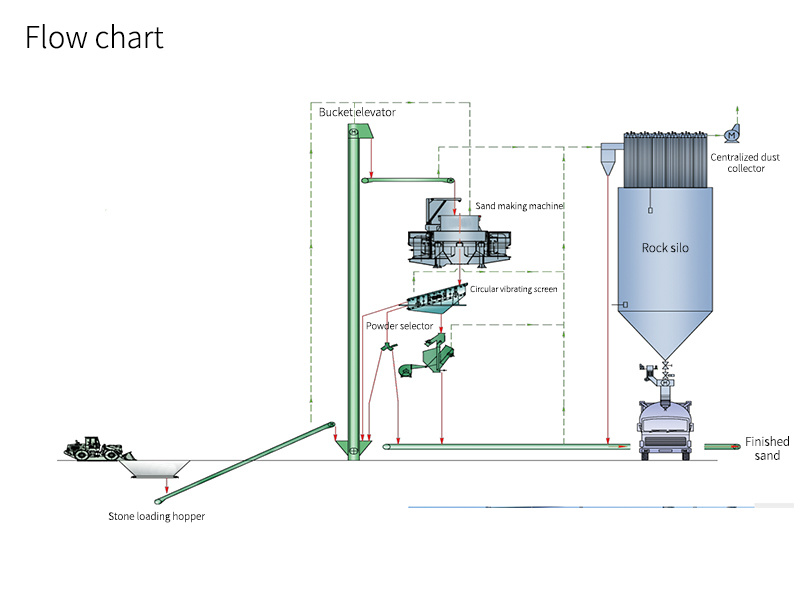

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?