Description

Workshop type dry mortar production line is applied to special dry mortar with low investment and small footprint. This type can be installed in the standard industrial plant with a simple and flexible structure and fast construction speed.

Main Components

1. Raw Material Storage Silos: Store bulk materials such as cement, sand, and additives.

2. Weighing System: Precisely measure the raw materials according to the formulas.

3. Mixing Unit: A high-efficiency mixer ensures uniform blending of all ingredients.

4. Packaging Machine: Package the finished product into bags or bulk containers.

5. Dust Collection System: Minimize dust emissions, ensuring a clean working environment.

6. Control System: An automated PLC control system manages the entire production process.

Applications

Construction projects requiring high-quality dry-mixed mortars.

Small to medium-sized dry mortar manufacturers.

Customized mortar production for specific applications.

Its technical parameters are as follows:

Model | Mixer | Power(kw) | Theoretical capacity(t/h) | Floor area(m²) |

GSW2000 | SW2000 | 200 | 40 | 400 |

GSW4000 | SW4000 | 320 | 70 | 550 |

GDW500 | DW500 | 120 | 10 | 200 |

GDW1200 | DW1200 | 150 | 20 | 300 |

GDW2000 | DW2000 | 200 | 40 | 400 |

GDW3000 | DW3000 | 240 | 50 | 400 |

Floor Mortar Workshop Type Production Line

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

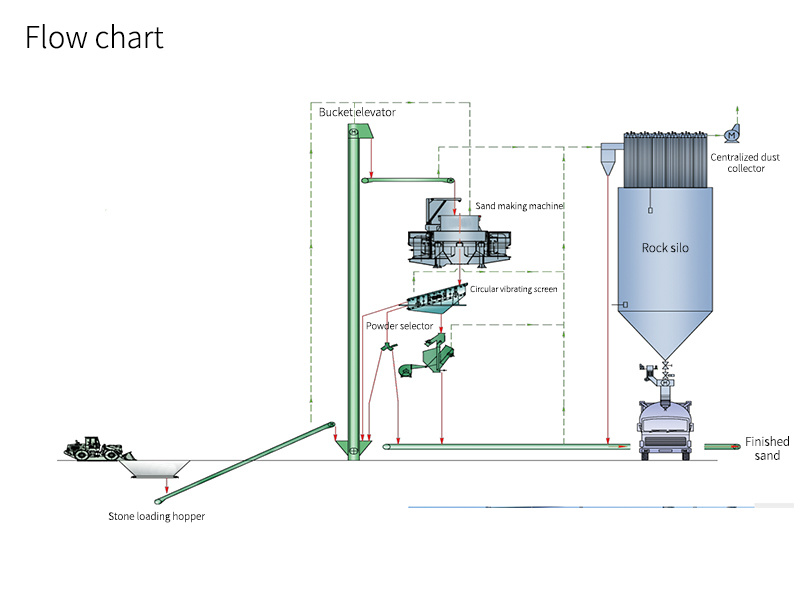

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?