Description

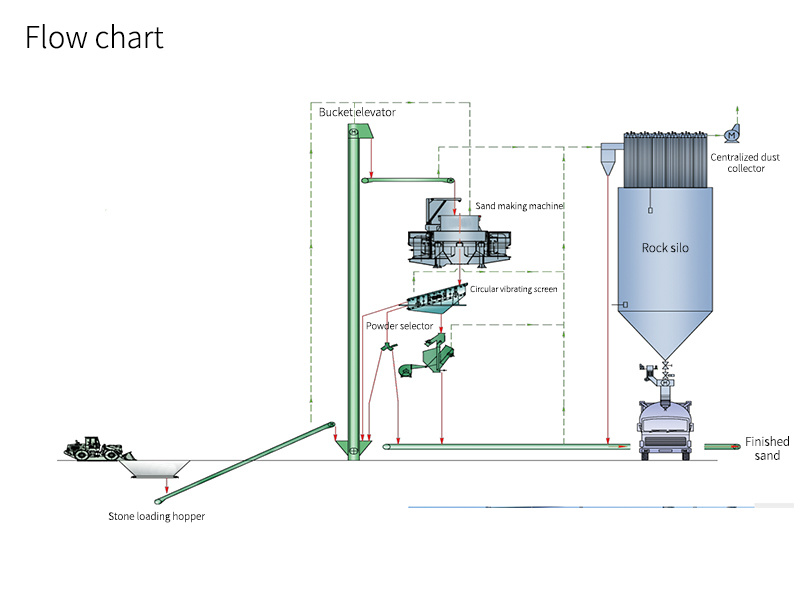

Screw conveyor in a dry mortar plant is a vital device for material transportation, which is widely used in the dry powder mortar production process. The following is a detailed introduction:

Working Principle

● Material Feeding: The dry powder mortar is fed into the inlet of the screw conveyor. This can be achieved through gravity from a storage bin or by using other feeding devices.

● Screw Rotation: Driven by a motor, the screw shaft rotates. The spiral blades on the shaft push the dry powder mortar along the inner surface of the conveyor trough or pipe.

● Material Conveyance: As the screw rotates, the dry powder mortar is continuously pushed forward in a helical motion, moving from the inlet to the outlet of the conveyor.

● Discharge: At the outlet, the dry powder mortar is discharged into the next processing unit or storage area.

Types

● Horizontal Screw Conveyor: It is mainly used for horizontal transportation of dry powder mortar. It has a simple structure and is suitable for transporting materials over short to medium distances.

● Vertical Screw Conveyor: Designed for vertical lifting of dry powder mortar. It requires a stronger screw shaft and motor to overcome the force of gravity and transport materials to a higher position.

● U-shaped Screw Conveyor: The conveyor trough is U-shaped, which can prevent material leakage to a certain extent and is suitable for transporting materials that are easy to spill or have a certain viscosity.

Advantages

● Continuous Transportation: It can achieve continuous and stable transportation of dry powder mortar, improving production efficiency.

● Simple Structure: With few moving parts, it is easy to install, maintain and operate.

● Sealed Transportation: It can be sealed to prevent dust from escaping, reducing environmental pollution and material loss.

● Versatile: It can be adjusted in length and speed according to different production requirements to adapt to various transportation needs.

Applications

● Raw Material Feeding: It is used to transport raw materials such as cement, sand and additives from storage areas to mixing equipment in a dry powder mortar plant.

● Intermediate Transfer: In the production process, it is used to transfer semi-finished products or mixed dry powder mortar between different processing units.

● Finished Product Delivery: It can transport the finished dry powder mortar to packaging machines or storage silos for further processing or storage.

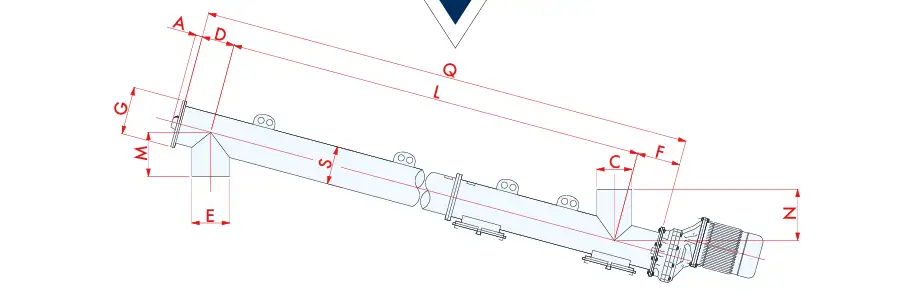

ΦS | 114 | 139 | 168 | 193 | 219 | 273 | 323 |

A | 56 | 56 | 40 | 40 | 40 | 40 | 40 |

C | on request nach Wunsch | ||||||

D | 120 | 120 | 140 | 150 | 160 | 180 | 220 |

E | on request nach Wunsch | ||||||

F | 140 | 140 | 160 | 170 | 180 | 220 | 220 |

L | on request nach Wunsch | ||||||

G | 190 | 190 | 250 | 250 | 275 | 330 | 405 |

M | on request nach Wunsch | ||||||

N | see WAM-standard siehe WAM-Norm | ||||||

Q | L+D+E | ||||||

Dimensions in mm | |||||||

TAG:

Screw Conveyor

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?