Equipment use

The drying system is widely used for drying raw materials of mechanism sand, yellow sand, various tailing sands, slag of cement plant, clay, coal, mixture, iron powder, building materials, chemical industry, foundry and other industries. The three-cylinder dryer is mainly used to dry granular materials within a certain range of humidity and particle size, such as dry mortar industry used in the mechanism of sand, river sand, sand, yellow sand, foundry industry with a variety of specifications of sand, building materials and cement industry with the blast furnace water quenching slag, steel slag, fly ash and so on.

Equipment features

1. The equipment covers a small area.

2. the moisture in the material to ensure that 0.5% or less, is a dry mortar and slag powder production line preferred products.

3. The thermal efficiency of cylinder self-insulation is up to more than 80%, which improves the thermal efficiency by 45%.

4. Fuel can be adapted to coal, oil, gas biofuel and so on. Can dry the block, granule, powder material below 20CM.

5. than a single cylinder dryer to reduce the footprint by 50%, civil investment by 50%, power consumption by 60%.

6. Made of alloy steel plate, 4 times more wear-resistant than ordinary steel.

7. according to user requirements can be easily adjusted according to the required final moisture index.

8. Low temperature of out gas, long time of using dust removal equipment.

9. No need for large and small gears to rotate, adopting pallet rotation.

10. Discharge temperature is lower than 60 degrees Celsius, continuous production and packaging.

Technical Parameters

Project unit | φ2.0x6m | φ2.5×6.5m | φ2.7×7m | φ3x7m | φ3.2x7m | φ3.6×8m | φ4.2×8.5m | |

Outer cylinder diameter (m) | 2.0 | 2.5 | 2.7 | 3 | 3.2 | 3.6 | 4.2 | |

Outer cylinder length(m) | 6 | 6.5 | 7 | 7 | 7 | 8 | 8.5 | |

Cylinder volume(m³) | 18.84 | 31.89 | 40.5 | 49.46 | 56.26 | 81.38 | 118 | |

Cylinder speed(rpm) | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 | |

Residence time of material(min) | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | 12-30 | |

Initial moisture of material (%) | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | |

Final moisture of material (%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

Maximum inlet air temperature (℃) | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ | 750-900℃ | 750-90o℃ | |

Production capacity | Slag | 15-20 | 20-25 | 25-30 | 30-35 | 35-40 | 45-60 | 65-80 |

Coal ash | 5-12 | 12-16 | 15-20 | 18-22 | 20-25 | 25-40 | 40-58 | |

Quicksand | 15-22 | 20-35 | 22-40 | 25-40 | 30-45 | 50-70 | 70-90 | |

Motor model | Yr160m-4 | Yr132m-4E | Yr160m-4 | Yr160m-4 | Yr132m-5E | Yr160m-4E | Yr160m-4E | |

Motor power(kw) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 11×4 | 15×4 | 18.5×4 | |

Reducer model | XWD-6 | XWD-6 | XWD-6 | XWD-6 | XWD-6 | XWD-8 | XWD-8 | |

Reducer speed ratio (I) | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 | 17-29 | |

Equipment weight (T) | 22 | 27 | 30 | 33 | 38 | 52 | 72 | |

TAG:

Dry Mortar Plant Drying System

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

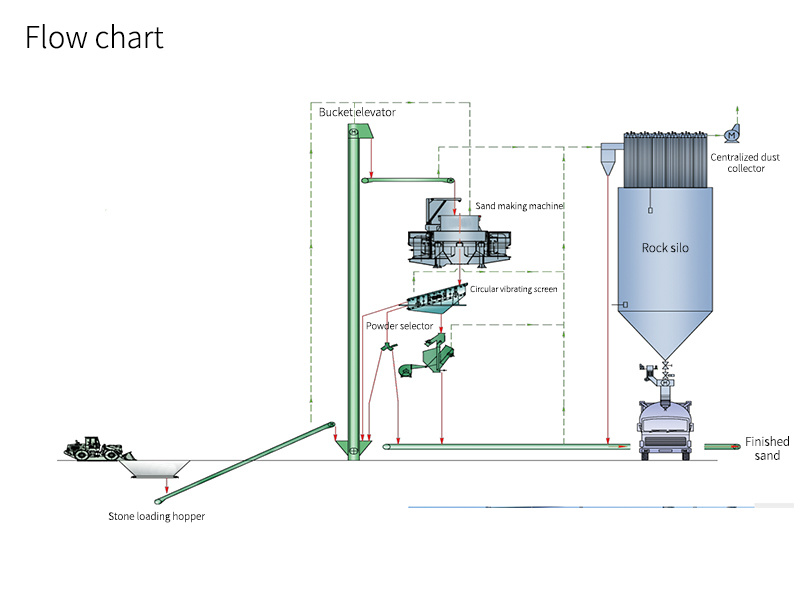

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?