Description

The vibrating screen, also known as a vibrating separator or screening machine, is a versatile and efficient piece of equipment used to separate and classify materials based on particle size. It is widely utilized in industries such as mining, construction, agriculture, food processing, and recycling. The vibrating screen operates by using vibration to move and separate materials, ensuring accurate sizing and efficient processing.

Key Features

1. High Efficiency: The vibrating screen uses vibration to quickly and effectively separate materials, ensuring high throughput and productivity.

2. Adjustable Screening Parameters: The amplitude, frequency, and angle of the screen can be adjusted to suit different materials and screening requirements.

3. Durable Construction: Built with robust materials, the vibrating screen is designed to withstand heavy-duty operations and harsh environments.

4. Multi-Layer Screening: Available in single or multi-layer configurations, allowing for the classification of materials into multiple size fractions simultaneously.

5. Low Maintenance: Simple design and easy access to components reduce maintenance requirements and downtime.

6. Wide Range of Applications: Suitable for dry or wet screening, as well as handling various materials, from fine powders to coarse aggregates.

Applications

● Mining: Screening and classifying ores, coal, and minerals.

● Construction: Separating aggregates, sand, and gravel for concrete and asphalt production.

● Agriculture: Sorting grains, seeds, and fertilizers.

● Recycling: Separating recyclable materials such as plastics, metals, and glass.

● Chemical Industry: Screening powders and granules for chemical processing.

● Food Processing: Sorting and grading food products like sugar, flour, and spices.

Advantages

● High Accuracy: Provides precise separation of materials based on size.

● Versatility: Can handle a wide range of materials and screening conditions.

● Compact Design: Saves space while maintaining high efficiency.

● Customizable: Available in various sizes, screen mesh types, and configurations to meet specific needs.

● Energy-Efficient: Designed to minimize power consumption while maximizing performance.

Its technical parameters are as follows

Model | Layers | Screen area/㎡ | Processing power/(t/h) | Power/kw | Weight/T |

YK2160 | 1 | 12.6*1 | 300-560 | 22 | 7.8 |

2YK2160 | 2 | 12.6*2 | 300-560 | 30 | 7.5 |

3YK2160 | 3 | 12.6*3 | 300-560 | 30 | 8.2 |

YK2460 | 1 | 14.4*1 | 450-650 | 22 | 7.8 |

2YK260 | 2 | 14.4*2 | 450-650 | 30 | 8.5 |

3YK2460 | 3 | 14.4*3 | 450-650 | 37 | 9.2 |

2YK2470 | 2 | 16.8*2 | 480-680 | 2*22 | 9.1 |

3YK2470 | 3 | 16.8*3 | 480-680 | 2*22 | 10.7 |

2YK3070 | 2 | 21*2 | 600-800 | 2*30 | 16 |

3YK3070 | 3 | 21*3 | 600-800 | 2*30 | 17 |

TAG:

Vibrating Screen with Layers

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

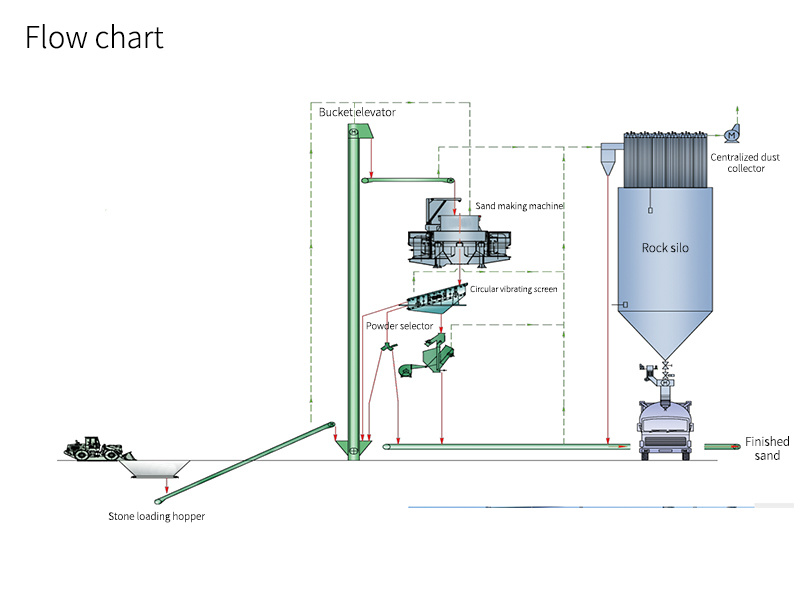

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?