Description

Dust collector in a dry mortar plant is an essential device for purifying air and collecting dust particles. It plays a crucial role in ensuring a clean and safe working environment. The following is a detailed introduction:

Working Principles

● Filtering Principle: Many dust collectors use filter bags or filter cartridges. The dusty air from the dry powder mortar production process enters the collector. As the air passes through the filter material, dust particles are trapped on the surface of the filter, while the clean air passes through and is discharged.

● Cyclone Principle: Some dust collectors adopt a cyclone structure. The dusty air enters the cyclone chamber and rotates at a high speed. Due to the centrifugal force, the dust particles with larger mass are thrown to the wall of the cyclone and then fall into the dust hopper at the bottom, while the relatively clean air flows out from the center.

Types

● Bag Filter: It has high filtration efficiency, capable of filtering out fine dust particles. It is widely used in dry powder mortar plants and is suitable for handling large air volumes.

● Cyclone Dust Collector: It is simple in structure and has low resistance. It is often used for preliminary dust removal of coarse particles in dry powder mortar production lines.

● Electrostatic Precipitator: It uses electrostatic force to adsorb dust particles, with high dust removal efficiency and low energy consumption, but has a relatively high cost and complex maintenance.

Advantages

● Effective Dust Removal: It can significantly reduce the dust content in the air, improving the air quality in the workshop and reducing environmental pollution.

● Improved Product Quality: By removing dust, it helps to prevent dust from contaminating the dry powder mortar products, ensuring the quality and performance of the products.

● Enhanced Equipment Lifespan: Reducing dust in the air can also prevent dust from entering production equipment, reducing wear and tear and extending the service life of the equipment.

Applications

● Mixing Area: It is used to collect dust generated during the mixing process of dry powder mortar to keep the mixing workshop clean.

● Packaging Area: When the dry powder mortar is being packaged, a large amount of dust is produced. The dust collector can effectively capture this dust to avoid dust pollution in the packaging area.

● Storage and Conveying Area: Dust collectors are also installed in the storage silos and conveyor belts to collect dust generated during material storage and transportation.

TAG:

Pulse Bags Dust Collector

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

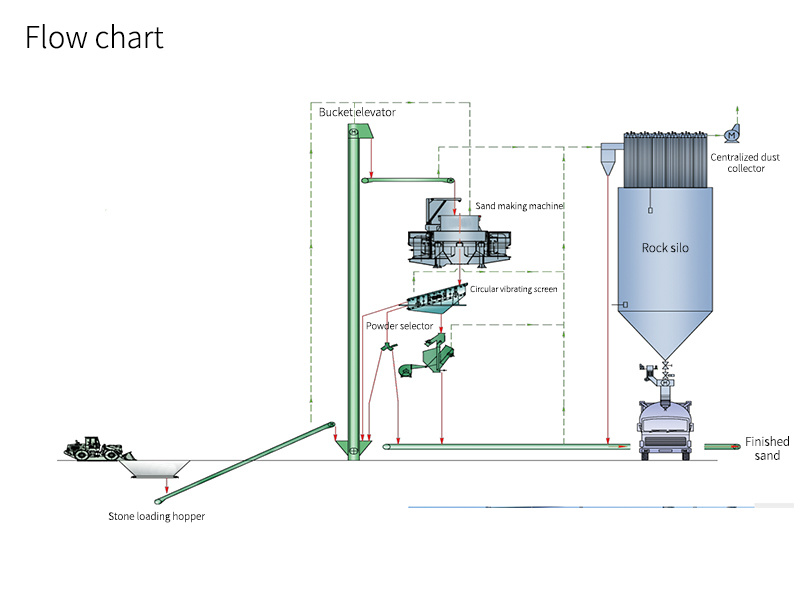

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?