Description

Automatic robotic bag palletizers are generally used in the dry mortar production line. It makes the existing dry mortar loading unattended, replaces manual working, prevents workers from inhaling dust to cause various lung diseases, turns the harsh environment into machine automation, improves working conditions, and improves economic benefits. A fully automatic packaging system improves the degree of automation, the highest cost of labor-saving.

Robotic bag palletizer is with independently programmable layer and pallet pattern programs. It is possible to palletize two packaging lines together. In addition, palletizing robots offer very controlled soft start and stop, resulting in unmatched accuracy, long life, and deficient noise levels. A palletizing robot puts cartons and packed goods on the pallet according to a particular arrangement for automatic stacking, stacking multilayer.

The robotic bag palletizer adopts PLC and touchscreen control to realize intelligent operation management that is simple and easy to master. It can significantly reduce the labor force and reduce labor intensity.

The palletizing robot can be roughly divided into the mechanical, control, and sensing parts. Each department works closely together. An automatic robot palletizing system has unique advantages in various individual and harsh environments, regardless of the degree of freedom, positioning accuracy, working range, or carrying capacity. The automatic robotic bag palletizer is a high-tech mechatronics product; it can meet the needs of different outputs. The optimized design makes the shape of the stack tight and neat.

A robotic bag palletizer covers a small footprint, and has 360-degree rotation, more flexible operation, and grab palletizing ability that can reach 800-1200 packages/hour. Palletizers for dry mortar bag specifications and sizes can be customized. Robotic bag palletizer work can be manual, semi-automatic, or automatic control with precision and high sensitivity.

Advantages of Palletizing System

Compact structure, small footprint, high site use efficiency.

The arm is light, the application is flexible, and the palletizing style is diverse and customized.

Less components, easier maintenance.

All axes adopt high-performance absolute servo system to ensure line optimization and overall excellent performance.

Through the servo system to carry on the accurate operation and the motion control. The repetition localization accuracy is high and the security is reliable.

The PLC control system allows you to monitor and control from anywhere, including a history of events, so that we can efficiently perform the final diagnostic work remotely, operate the machine, etc.

Bag palletizer ability to palletize bags of different weights, 20 kg, 40 kg, etc.

The entire perimeter has the necessary physical fencing and photoelectric safety barriers.

Choosing the right robotic bag palletizer usually depends on the following factors: payload, range, duty cycle, cycle time, and footprint.

The technical parameters are as follows

Packing speed | 600-1000bags/hour |

Packing weight | 10-50kg |

Power supply | 380V 50Hz Triple-PHA, 4Wires |

Stacking layers | 1-12 |

Pallet requirements | Customize |

Bags | Open mouth woven bag, valve bag, gusset bag, poly liner, etc. |

Optional | Wrapping machine, coding machine, etc. |

TAG:

Palletizing Robot Arm System

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

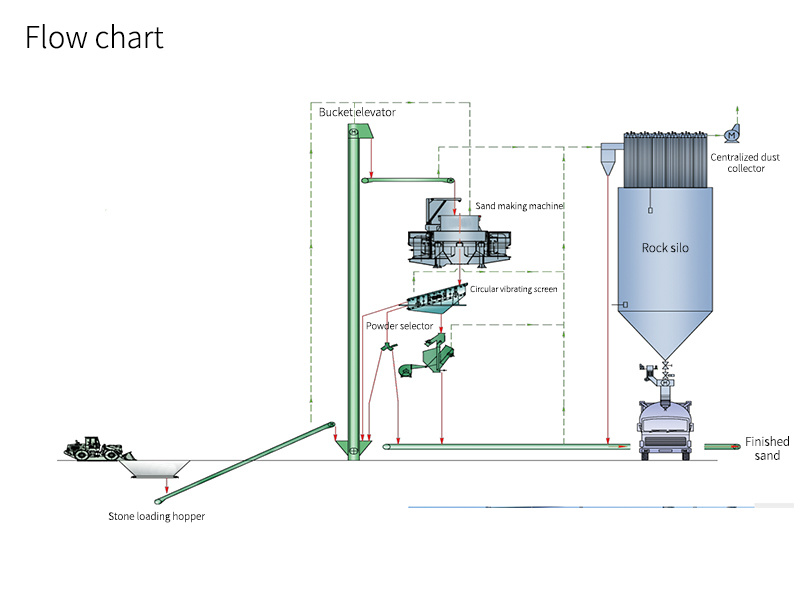

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?