Description

Double Horizontal Shaft Mortar Mixing Machine is a key piece of equipment in the dry mortar production line, known for its high mixing efficiency and excellent mixing quality.

Structure

● Twin Shafts: It is equipped with two parallel horizontal shafts, on which a series of paddles are evenly distributed. The shafts rotate in opposite directions to drive the paddles to mix materials.

● Mixing Chamber: The mixing chamber is usually made of wear-resistant materials to withstand the friction and impact of materials during the mixing process. It has an appropriate volume to hold a certain amount of materials for mixing.

● Drive System: Consists of motors, reducers and couplings. The drive system provides the necessary power to ensure the stable rotation of the twin shafts at the required speed.

Working Principle

● Strong Convection Mixing: As the two shafts rotate, the paddles on them drive the dry mortar materials to move in different directions, creating a strong convection effect. This enables materials to be continuously shuffled and exchanged, achieving rapid and uniform mixing.

● Shear Mixing: The paddles on the shafts also generate a certain shear force during rotation. This force helps to break up agglomerated materials and further improves the mixing uniformity, especially for materials with different particle sizes and densities.

Advantages

● High Mixing Efficiency: It can complete the mixing task in a relatively short time, increasing production efficiency.

● Uniform Mixing: It can ensure the uniform mixing of various materials in dry mortar, improving product quality stability.

● Good Versatility: It can be used to mix different types of dry mortar, such as ordinary mortar, special mortar and so on.

The technical parameters are as follows:

Model | Volume/L | Power/KW | Weight/KG | Load factor | Flying-cutter/SET |

SW500 | 500 | 7.5 | 1000 | ≤0.7 | 4 |

SW1000 | 1000 | 11-15 | 2500 | ≤0.7 | 4 |

SW2000 | 2000 | 18.5-37 | 3500 | ≤0.7 | 4 |

SW3000 | 3000 | 37-45 | 4000 | ≤0.7 | 4 |

SW4000 | 4000 | 45-75 | 5000 | ≤0.7 | 4 |

SW6000 | 6000 | 75-100 | 6000 | ≤0.7 | 6 |

SW10000 | 10000 | 100-150 | 9000 | ≤0.7 | 6 |

Double Horizontal Shaft Mortar Mixing Machine

Contact Us

Classification

Customer visits

Packaging and Shipping

FAQs

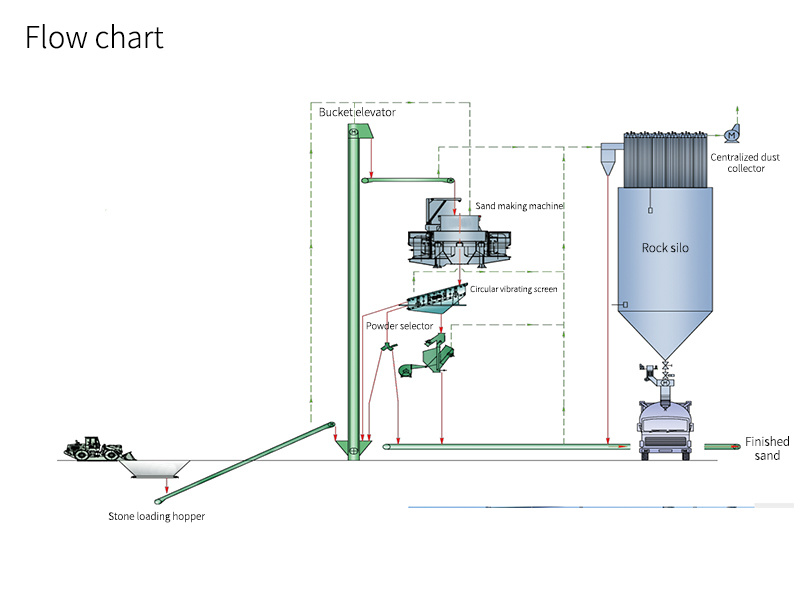

My site is not in an ordinary location. Could you provide a corresponding plan to build a dry mortar production line for me?

What sand-making equipment is used in the dry mortar production line?

What kind of sand making machine are you using? Is the crushing effect good?

What should I do if the aggregate conveyed by the belt is uneven?

What problems will occur with dry-mix mortar admixtures in high-temperature weather?

What problems will occur with dry-mix mortar raw materials in high-temperature weather?

Can engineers be sent to our site for installation and training?

What is the positioning and cost performance of your products?

Are you a factory, a design company, or a trading company?

Can you provide technical and process guidance?

I don't have the formula, can you send me one?